Anodizing

Anodizing

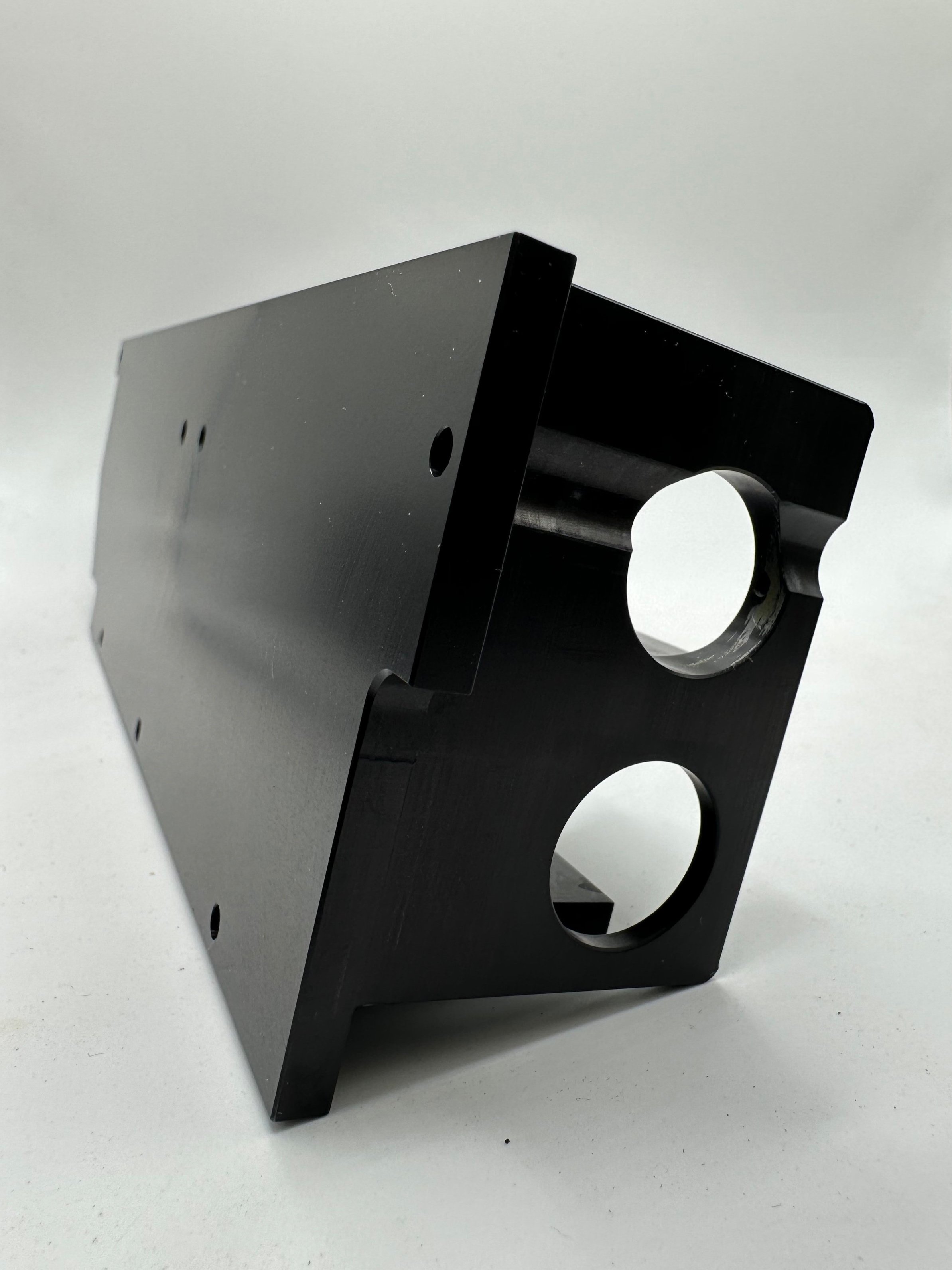

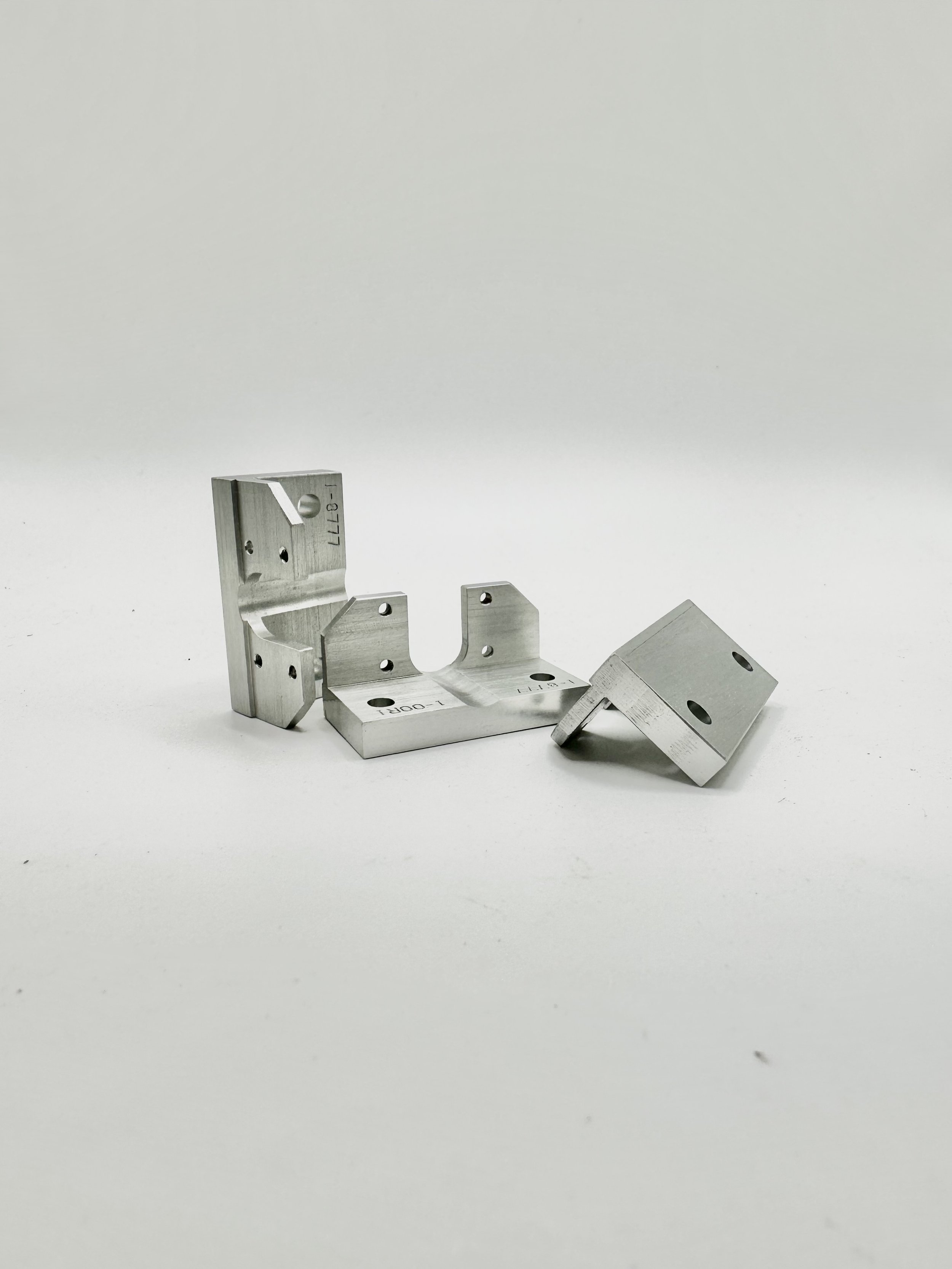

Anodizing is an electrochemical process used to create a durable and protective oxide layer on the surface of metals, primarily aluminum. It involves immersing the metal part, known as the workpiece, in an electrolyte bath and applying an electric current to promote the formation of an oxide coating.

The benefits of anodizing include:

Corrosion Resistance: The anodized oxide layer provides excellent corrosion resistance, protecting the underlying metal from environmental elements, chemicals, and wear.

Hardness and Wear Resistance: Anodizing significantly increases the surface hardness of the metal, making it more resistant to scratches, abrasion, and wear.

Aesthetic Options: Anodized aluminum can be produced in a variety of colors, providing an opportunity for aesthetic customization. This is especially useful in architectural applications or industries where appearance is important.

Electrical Insulation: The anodized oxide layer acts as an electrical insulator, making anodized aluminum suitable for applications where electrical conductivity needs to be controlled or prevented.

Anodizing is widely used in industries such as aerospace, automotive, construction, electronics, and consumer goods. The specific anodizing process, including bath composition, current density, and temperature, can be adjusted to achieve desired coating thickness, appearance, and performance characteristics.