Chemical

Conversion

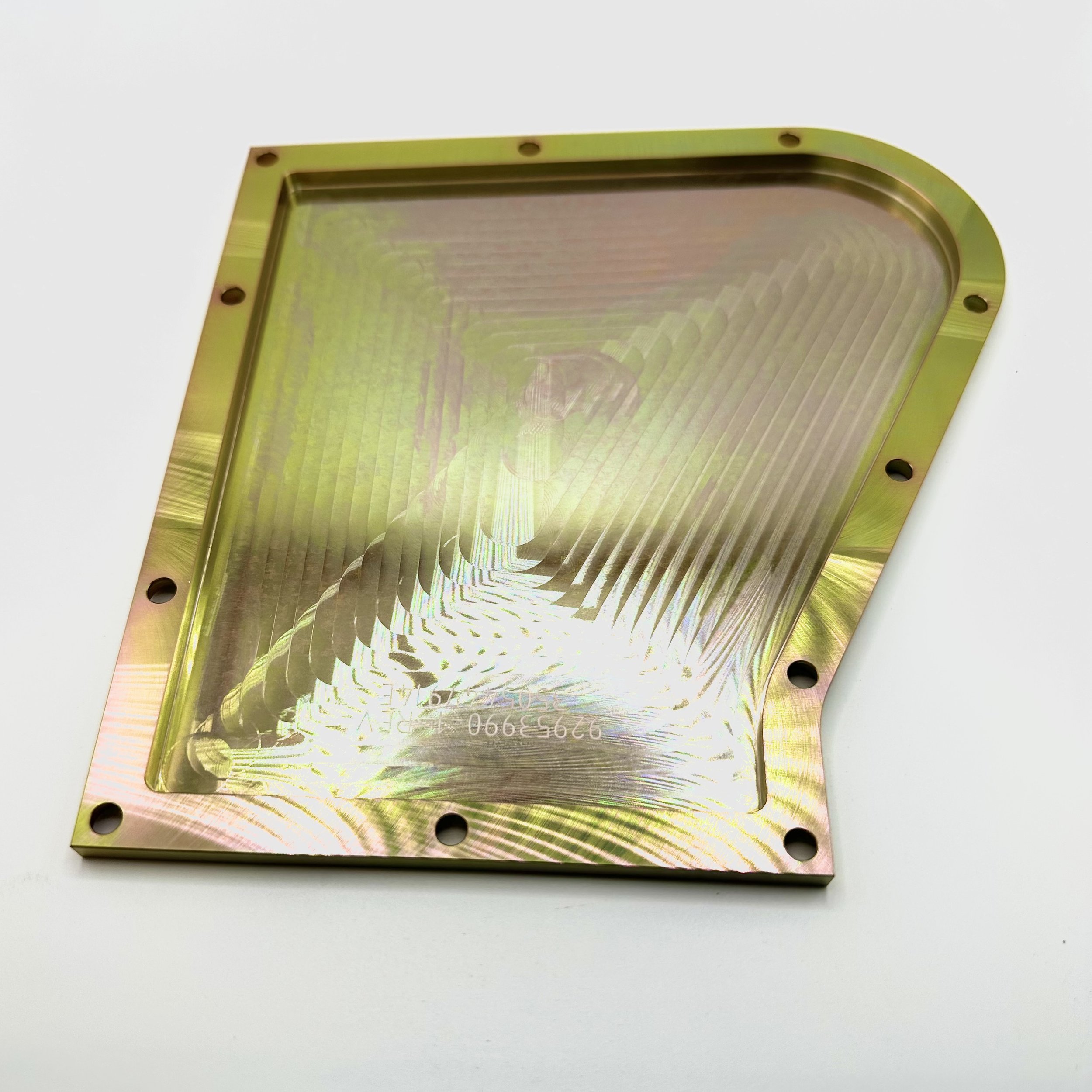

Chemical Conversion Coating

Aluminum chemical film, also known as aluminum chromate conversion coating or simply chem film, is a chemical treatment applied to the surface of aluminum to enhance its corrosion resistance and provide a suitable base for subsequent paint or adhesive applications. It is a common surface preparation technique used in various industries, including aerospace, automotive, and electronics.

The chem film process involves immersing the aluminum surface with a solution containing chromium compounds, such as hexavalent chromium or trivalent chromium, along with other proprietary chemicals. These chemicals create a thin, protective layer on the aluminum surface through a chemical reaction with the metal.

The resulting chem film coating provides several benefits, including:

Corrosion protection: The chem film layer acts as a barrier between the aluminum and the environment, protecting it from corrosion caused by moisture, chemicals, and other corrosive agents.

Adhesion promotion: Chem film enhances the adhesion of subsequent coatings, such as paint or adhesives, improving their durability and performance.

Electrical conductivity: Chem film coatings can maintain the electrical conductivity of the aluminum substrate, making them suitable for applications where electrical grounding or conductivity is required.

Aesthetics: Chem film can provide a uniform and aesthetically pleasing surface finish to the aluminum, often resulting in a light yellow or iridescent appearance.